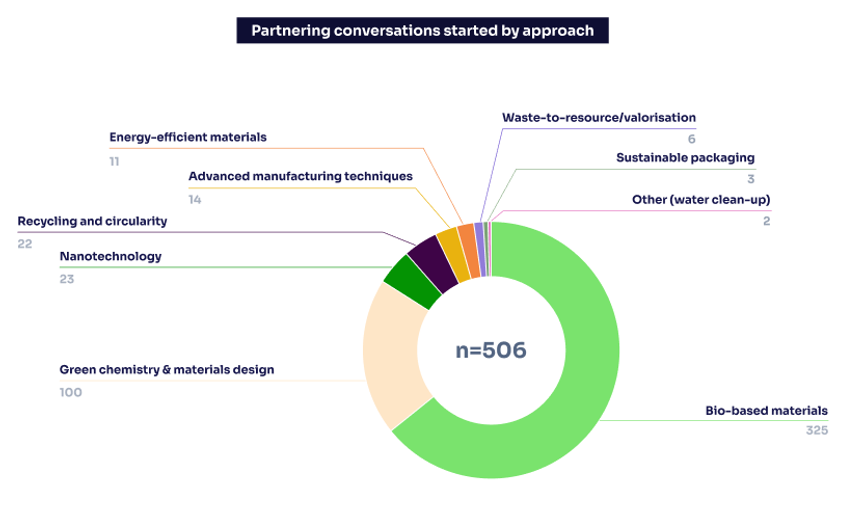

Chemical & material sustainability R&D trends and breakthrough innovations

This report identifies the latest trends in sustainable materials and green chemistry R&D, providing scientific decision-makers with a roadmap of high-impact opportunities, emerging technologies, and potential future partners.

Inpart's R&D trends reports and online partnering platform aim to provide access to the most-promising, exclusive, and previously unsurfaced early-stage research and assets, helping accelerate the development of new sustainable technologies and innovations.

Download the report

Key R&D challenges for sustainable materials and green chemistry

We are extracting resources to produce goods and services that our planet can’t replenish. To preserve our environment and ecosystems, we must develop sustainable resource cycles, minimizing waste and depletion. Innovations in material sustainability, energy-efficient processes, and recycling technologies are key to creating a cleaner and more resilient future.

Consumer demand for sustainability is increasing, and research is essential to developing ecology-friendly alternatives that maintain and deliver performance. It’s also essential that sustainability is ingrained into the R&D process instead of being added as an afterthought, as 70%-80% of a product’s environmental impact is determined during the research and development phase.

Challenge #1

Embedding an end to the life of materials

Many products and materials are not designed to be disposed, recycled, or degraded. Complex material composition, lack of recycling infrastructure, and contamination make it difficult to reclaim or repurpose materials, which leads to landfill waste, pollution and resource depletion. To lower emissions and meet SDG’s, it is vital we plan better for the end of a material’s life when designing the product.

Challenge #2

Greening chemistry

Making chemistry greener requires redesigning and recalibrating traditional processes in order to minimize environmental impact while maintaining performance and cost-effectiveness. This is a challenge as many industrial materials rely on toxic solvents, energy-intensive synthesis, and non-renewable feedstocks. Advances in green chemistry, such as bio-based polymers, solvent-free synthesis, and catalytic processes, could be transformative.

Challenge #3

Balancing performance with sustainability

Many ecology-friendly material alternatives often struggle to match the strength, durability, and functionality of 'traditional’ materials. Sustainable alternatives may also have higher upfront costs, and despite being cheaper in the long run, some companies are be reluctant to adopt them, prioritizing more immediate profits over long-term sustainability.

Listen to an audio digest of the editorial and report introduction

Top chemical & material sustainability innovations

Review the highest performing chemical and material sustainability projects and technologies from our online partnering platform.

To read the full summary article for each technology, asset or project, and to connect with the team developing them, you will need to join our online partnering platform.

1. A bioinspired and biodegradable antibacterial coating

Globalization and ageing populations have increased the risks of disease transmission. Furthermore, awareness of surface transmission grew during the COVID-19 pandemic. However, concerns around the sustainability and composition of current approaches requires innovation to create for ecology-friendly coatings and disinfectants.

Durham University researchers have developed a sustainable, biodegradable antibacterial coating from natural products. Their versatile and cost-effective technology can be applied to various surfaces, offering high levels of antibacterial efficacy and long-lasting performance. Their innovation can be adapted for food packaging, medical equipment, and textiles, with the team seeking industry partners for commercialization.

2. Making biodegradable bioplastics from agricultural waste

As we shift to a more sustainable global economy, many industries are striving to replace single-use plastics with greener alternatives such as bioplastics. However, many current solutions still face challenges including the cost of raw materials and manufacturing.

Working to overcome these barriers, researchers at the University of British Columbia have developed what they call Grasstic - a strong, flexible, transparent, and biodegradable packaging material made from agricultural waste. Their ecology-friendly process uses minimal chemicals, relying primarily on water. The team are seeking partners for co-development to help bring their solution to market.

3. Embedding degradation into cross-linked polymers

Compared to linear polymers, cross-linked thermosets deliver superior stability, tensile strength and elasticity. They are widely used in insulators and transportation, with 15-20% of all polymers now being crosslinked, but their robust thermochemical properties makes them non-recyclable. As a result, they are typically incinerated or put into landfill.

At the University of Manchester, researchers have developed new cross-linked polymer systems that retain the high performance of thermoset materials and their composites while adding controlled degradation through selective chemical recycling or biodegradation. Their technology should provide new affordable routes to fully degradable elastomeric and rigid polymeric materials from sustainable sources. The team are seeking partners for testing, development and licensing.

4. Making lubricants from plants

Lignin, a plant-derived biopolymer,remains underutilized in materials chemistry due toproperties including its dark color, odor, molecular weight, and limited reactivity. As a result, itis oftenrelegated to low-value applications.Unlocking the potential of lignin could open up new opportunities for material sustainability.

Researchers at the University of Delaware have synthesized biobased lubricant base oils from lignin. Their green technology matches the performance of petroleum-based alternatives while significantly reducing carbon footprints, paving the way for more sustainable high-performance lubricants. The team are seeking licensing and collaborators.

5. Creating degradable thermosets from bio-derived monomers

60-million tons of thermoset plastics are discarded annually due to a lack of efficient recycling methods. These materials are robust but non-degradable, creating a need for recyclable thermosets with similar properties.

At Cornell University, researchers have developed thermosets made from bio-sourced monomers using a single-vessel polymerization method. They are depolymerizable through heat, acid hydrolysis, or oxidation. Their technology is suitable for both soft, flexible materials and stiff, tough materials in fields including medical devices, coatings, adhesives, and 3D printing. The team at Cornell are seeking partners for development, licensing and commercialization.

Advance your partnering strategy

Speak with our partnering experts to review your partnering goals and learn how our network, solutions and tools can help accelerate your programs and initiatives.